What News in Spill Containment?

New Flexible Spill Berms!

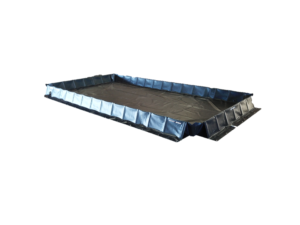

Introducing the Ready Ultra-Light Spill Berm™

30-40% Lighter than the Original Ready Berm.

Made in America!

Mil-Spec Berry Amendment Fabric.

Designed to provide Secondary Containment of Fuels in combat situations.

Innovations in spill control technology have significantly evolved in recent years, driven by a growing awareness of environmental concerns, stricter regulations, and the need for more effective and efficient spill response. These advancements not only enhance environmental protection but also improve the overall safety and cost-effectiveness of spill control measures. Here are some notable innovations in spill control technology:

- Automated Spill Detection Systems: Utilizing sensors, cameras, and artificial intelligence, these systems can detect spills in real-time. When a spill is identified, they can trigger alarms and automated responses, allowing for rapid containment and response.

- Remote Monitoring and Control: Advanced technology allows for remote monitoring of spill control systems. Operators can receive real-time data on spill conditions, remotely control containment barriers, and make immediate adjustments to minimize the spread of contaminants.

- Internet of Things (IoT) Integration: IoT devices are increasingly being used to monitor the condition of spill control equipment, such as absorbents and barriers. They provide data on saturation levels, wear and tear, and can trigger maintenance alerts, ensuring equipment is always ready for use.

- Biodegradable Absorbents: Eco-friendly absorbent materials made from renewable resources or biodegradable materials are gaining popularity. These materials are effective in containing and absorbing spills while being environmentally responsible.

- Nanotechnology: Nanomaterials are being used to enhance the absorbency and efficiency of spill control products. Nanotechnology allows for smaller, more effective absorbents that can capture and contain spills more efficiently.

- Hydrophobic and Oleophilic Materials: These materials repel water and attract oil, making them ideal for oil spill containment. They can be applied to various surfaces, including booms and barriers, to selectively absorb hydrophobic substances.

- Spill Containment Booms with Built-in Skimmers: Some spill booms now come equipped with built-in skimming systems. These booms can both contain and recover spilled oil or hazardous liquids, reducing the need for additional cleanup equipment.

- Mobile Spill Response Apps: Mobile apps have been developed to streamline spill response efforts. They provide access to response plans, reporting tools, and communication systems, enabling a more coordinated and efficient response in the field.

- Drone Technology: Drones equipped with cameras and sensors can quickly assess the extent of a spill and help response teams plan and implement containment strategies more effectively.

- 3D Printing for Customized Solutions: 3D printing technology is being used to create customized spill control solutions, such as specialized barriers or equipment, tailored to specific industries or spill scenarios.

- Reusable Spill Products: Some companies are designing spill control products that can be cleaned and reused, reducing waste and long-term costs.

- Training Simulators: Virtual reality (VR) and augmented reality (AR) training simulators are being used to train spill response teams. These technologies offer realistic scenarios for practice, improving preparedness.

Incorporating these innovations into your spill response plan can significantly enhance your organization’s ability to respond to spills quickly, efficiently, and in an environmentally responsible manner. Staying up-to-date with the latest developments in spill control technology is crucial for maintaining effective spill response capabilities while also demonstrating a commitment to environmental sustainability.

How Much Oil Did Hurricane Laura Spill? Answer Is Still Unknown, But Sheen Is Widespread

https://weather.com/photos/news/2020-09-14-hurricane-laura-oil-spills

Mauritius Sees Largest Rally in 40 Years Over Oil Spills

https://www.africanews.com/2020/09/13/mauritius-sees-largest-rally-in-40-years-over-oil-spills/

Spill containment Berms, Berm Liners, Spill Pallets, and More.

They are featuring the latest in spill containment, spill prevention, and secondary containment products.

What is New from Ready Containment, LLC?

https://www.linkedin.com/company/ready-containment-llc-/

https://www.linkedin.com/showcase/spill_berms/

Check out the following hashtag on Linkedin:

https://www.linkedin.com/feed/hashtag/environment/

https://www.linkedin.com/feed/hashtag/sustainability/

https://www.linkedin.com/feed/hashtag/oilandgasindustry/

https://www.linkedin.com/feed/hashtag/mining/

Ready Containment, LLC. Contact us if you have a new secondary spill containment item and would like to post it.

Got News? Let Us Know About it.

Ready Berms are now available in 36″ wall heights for extra spill containment.

More containment in less space.

Let us know about it. So we can tell the world. This site is sponsored by Ready Containment, LLC., an ISO 9001:2015 Certified manufacturer of spill containment products, including Spill Containment Berm, Secondary Containment Pit Liners, and hazardous waste liners, and more. Our Featured spill containment products are our Spill Berms featuring our Ready Berm that come fully assembled and are delivered Ready To Go.

Ready Containment offers many newsworthy innovations in the spill berm and secondary containment market. We are always looking for new ideas in the containment industry. If you have a new product and are looking for a product development partner, call us at 941-739-9486.

Ready’s new Space Saver Marine Fuel Bladders gives you more space on your deck without giving up the extra fuel!

New Custom Baffled Bladders for Marine use.

Environmental News | Secondary Spill Containment

Please contact us to post your spill containment news at 941-739-9486

The Essential Guide to Spill Containment: Protecting Your Workplace and the Environment

In today’s industrial landscape, where the handling of hazardous materials is a routine part of operations, spill containment is not just a regulatory requirement—it’s a fundamental aspect of environmental stewardship and workplace safety. The accidental release of chemicals, oils, and other substances can have devastating consequences for both the environment and human health. This guide aims to shed light on spill containment, its importance, and the best practices for implementing effective spill containment strategies in your workplace.

Understanding Spill Containment

Spill containment refers to the process and practices involved in preventing spilled substances from spreading into the environment. It involves the use of various containment systems and products designed to capture, control, and clean up spills before they can cause harm.

Why Is Spill Containment Important?

The significance of spill containment transcends compliance with environmental regulations. It’s about safeguarding our natural resources, protecting wildlife, and ensuring a safe, healthful working environment for employees. Effective spill containment measures can also mitigate the financial impact of spills by avoiding costly cleanup operations and potential fines for regulatory non-compliance.

Types of Spill Containment Systems

Spill containment solutions vary widely, depending on the nature of the materials being handled, the volume of substances, and the specific needs of a facility. Here are some common types of spill containment systems:

Secondary Containment**: This involves creating a barrier or containment area around the primary storage containers. If a spill occurs, the secondary system contains the spill, preventing it from spreading. Examples include spill pallets, berms, and containment sumps.

Spill Kits**: Portable and designed for quick response, spill kits contain absorbents, protective gear, and cleanup tools tailored to specific types of spills, such as oil, chemical, or mercury spills.

Drain Covers and Seals**: These are used to block drains temporarily, preventing spills from entering waterways through the drainage system.

– **Absorbents**: Materials such as pads, rolls, and booms that soak up liquids. They are essential for cleaning up spills and are selected based on the type of liquid spilled.

Best Practices for Spill Containment

Implementing spill containment effectively requires a strategic approach tailored to the specific risks and needs of your facility. Here are some best practices to consider:

1. Risk Assessment**: Conduct a thorough assessment of your facility to identify potential spill hazards and determine the appropriate containment measures.

2. Training and Preparedness**: Ensure that all employees are trained on spill response procedures, including the use of spill containment systems and personal protective equipment (PPE).

3. Regular Inspections and Maintenance**: Regularly inspect containment systems and equipment for signs of wear or damage. Maintain all spill response equipment in ready-to-use condition.

4. Spill Response Plan**: Develop a comprehensive spill response plan that outlines procedures for addressing spills, including notification protocols, evacuation procedures, and cleanup operations.

5. Continuous Improvement**: Learn from incidents and near-misses. Regularly review and update spill containment strategies and response plans to reflect changes in operations or lessons learned from past spills.

Conclusion

Spill containment is a critical component of environmental protection and workplace safety. By understanding the types of containment systems available and implementing best practices tailored to your facility’s needs, you can minimize the impact of spills and uphold your commitment to protecting both your workforce and the environment. Remember, effective spill containment starts with preparedness and relies on the collective effort of everyone in the organization.